- Problems with fuel flow

- Problems with the spark

- Air/vacuum leaks

- Problems with the carburetor

- Problems with valve clearance

If the scooter starts, it must be getting some sort of spark, but the spark may be weak or there may be a problem with the ignition timing. The first thing to do is remove the spark plug and take a look at it. If there are heavy deposits on the tip (black or white), or if it looks worn or damaged or if the gap isn't what it should be, it should be replaced. You could clean it and regap it but plugs are cheap ($5 or less), so you should probably replace it anyway and see if the engine runs better. If there's no difference, at least you now have a spare plug if the one in the engine ever does fail!

Today there are very few scooter engines on which you can alter the ignition timing. All timing functions are done via the CDI (Capacitor Discharge Ignition) module. If it's bad, all you can really do is replace it. They're pretty reliable though, so that might be something to try if all else fails to find a problem.

Leaks in the air or vacuum lines can cause problems too. Usually it's leaks in the vacuum lines which control several functions related to the carburetor operation and fuel supply. First check all the vacuum line connection and the lines themselves for splits and cracks. If they look OK you can spray water on them while the engine is running and see if there is any change in engine speed. If there's a leak, the liquid will temporarily seal it and the engine will run better. Some recommend spraying WD40 or carburetor cleaning fluid on the lines, but if you do there can be a risk of fire, so be careful.

Carburetor problems are the most likely source of poor running. First check the idle speed and air/fuel mixture screws (see carburetor adjustment). If the adjustment is OK, or you can't get the engine to idle well, then comes the next step. Over time (especially if the scooter is stored for long periods of time with gas in the carburetor), "gummy" deposits can build up. These are the residues which are left behind when gas evaporates. They can clog internals valves, jets and passages inside the carburetor which can affect fuel flow. The best way to deal with them is to remove the carburetor from the scooter (see carburetor rejetting), take it apart and soak it in carburetor cleaning fluid, which will dissolve the deposits. Make sure the jets are clear too.

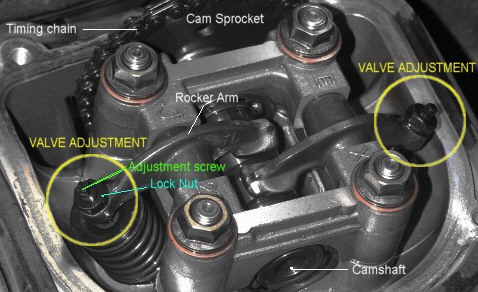

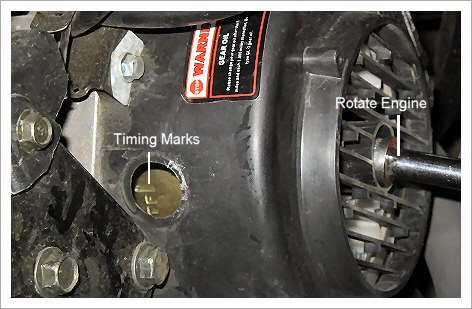

Valve clearance ("valve lash", "tappet clearance") can affect the way the engine runs. This is the clearance between the camshaft and the valve stem. If it is too large, the valve won't open all the way (and you'll get a loud "clattering" noise) and if it is too small (or non-existent), the valve may not properly close. Either way is a problem. You either won't get fuel/air into the cylinder properly or you won't get good compression and/or exhaust and the valve may overheat and suffer damage.

No comments:

Post a Comment