- Charging or powering a cell phone

- Powering a GPS unit

- Powering a Radar detector

- Powering an electric tire inflator

- Powering an auxiliary light

- Charging your scooter battery

- Powering heated gloves

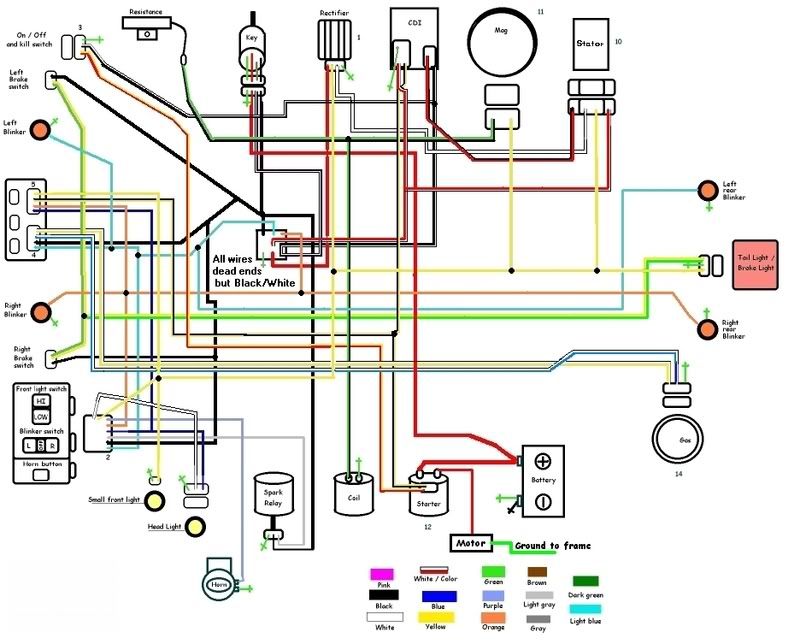

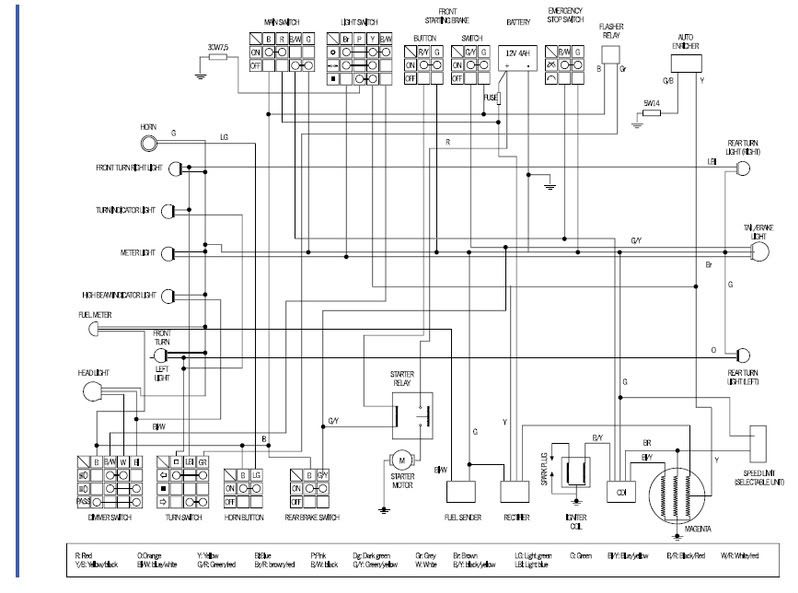

The socket can get its power from any 12v line. You can pick one that's activated by the ignition switch, or you can do what I did and connect it directly to the battery (via a fuse of course) so that you have power available at all times, not just when the ignition is turned on.

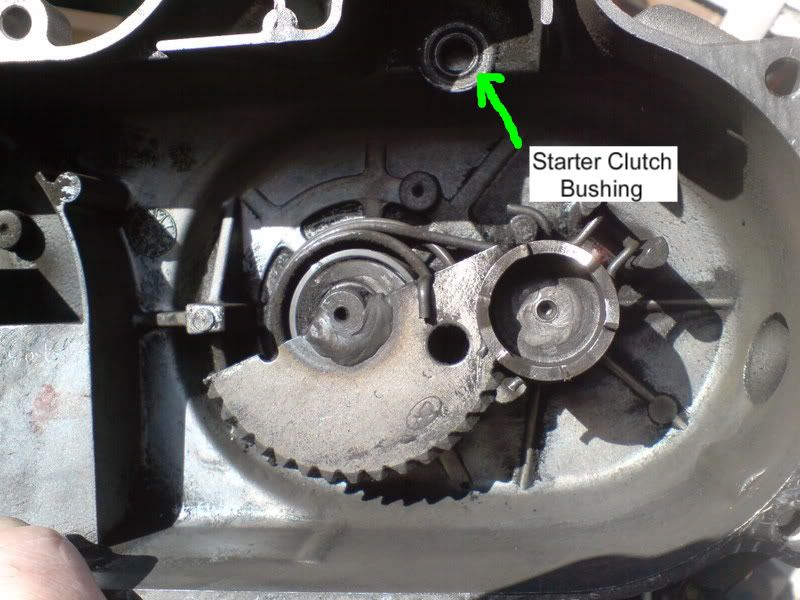

Most motorcycle batteries have a capacity in the 3-7 amp.hour range, so you can't draw a huge amount of power from them. My outlet is fused at 8 amps, which is enough for a 55W auxiliary light (which draws about 4 amps) or a tire inflater (typically 2-3 amps), heated gloves (typically 1-2 amps) and more than enough for any electronic gadget such as a radar detector or GPS unit (typically well under 1 amp). Don't try drawing huge amounts of power though. The battery is quite small and could run down quite quickly if the engine isn't running to recharge it. Even if the engine is running you could strain the alternator (generator) if you try to draw too much power.

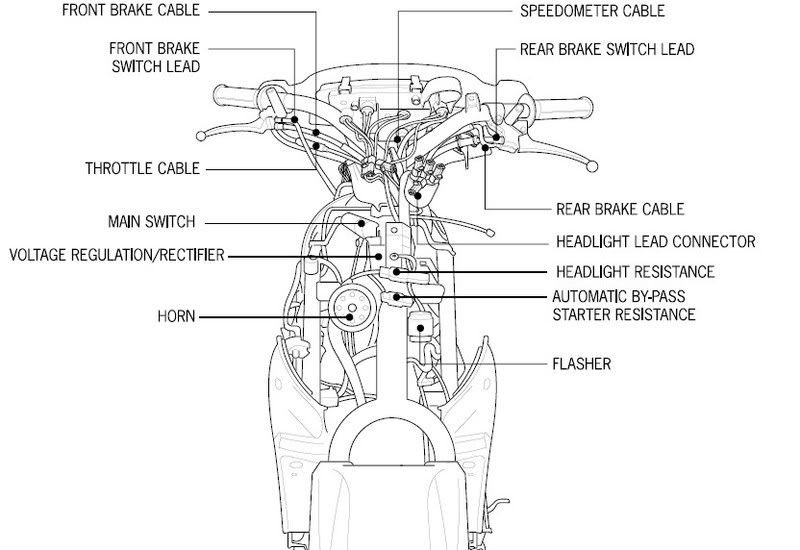

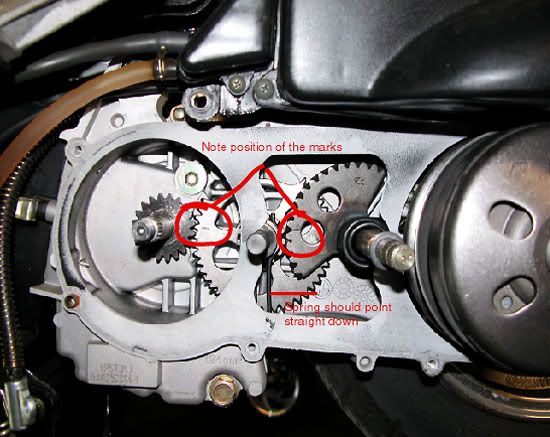

Installation of a 12v outlet is simple. The one I added mounted in a 1" diameter hole. I cut it out with a hole saw and smoothed the edges with a file. Since you're likely to be cutting the hole in plastic, this isn't a lot of work. The negative (black) lead connects to the chassis of the scooter. The red lead connects to the fuse and the fuse connects to the positive (+) terminal of the battery. Make sure the wires are secured using nylon cable ties so that they don't get caught up in any of the scooter's moving parts and they don't rub against any hot parts of the engine which could melt the insulation on the wires and cause a short circuit.

I also use the outlet to power a 12v tire inflator. The battery has plenty of power to inflate both the front and rear tires from 0 to 32 psi. After inflating both tires the scooter started right up, so there's no danger of running the battery down in normal use. Having the outlet available makes topping up the tires a simple job, and if it's easy to do you are more likely to do it.